Azure Depth Platform

3D vision & AI industry solutions on Azure

Latest posts

Time-of-flight camera characterization with functional modeling for synthetic scene generation

Staying at the forefront of 3D sensing technology development requires continuous investment and innovation. Microsoft's paper : “Time-of-flight camera characterization with functional modeling for synthetic scene generation”, which was recently published in "Optics express" is a clear demonstration of the depth (pun intended) we go to at Microsoft, to make sure partners and customers get the best 3D sensing capabilities possible - click here to read. In this manuscript, we design, describe, and present a functional model of Time-of-Flight (ToF) cameras. The model can be used to generate randomized scenes ...

How Do ToF Based Depth Cameras Improve Our Lives?

This installment of the Azure Depth Platform blog is co-authored by David Chen, Co-founder & Chief Executive Officer at Orbbec and Amit Banjeree, Co-founder & Technical Lead, Azure Depth Platform program. The concept of medical imaging was born in 1895 with the invention of the x-ray by a German professor of physics, Wilhelm Rontgen. X-ray paved the way for the more advanced imaging techniques used in medicine and forensic investigation such as CT (computed tomography) scans and MRI (magnetic resonance imaging). Today, optical fiber imaging has enabled medical professionals to see inside the body wit...

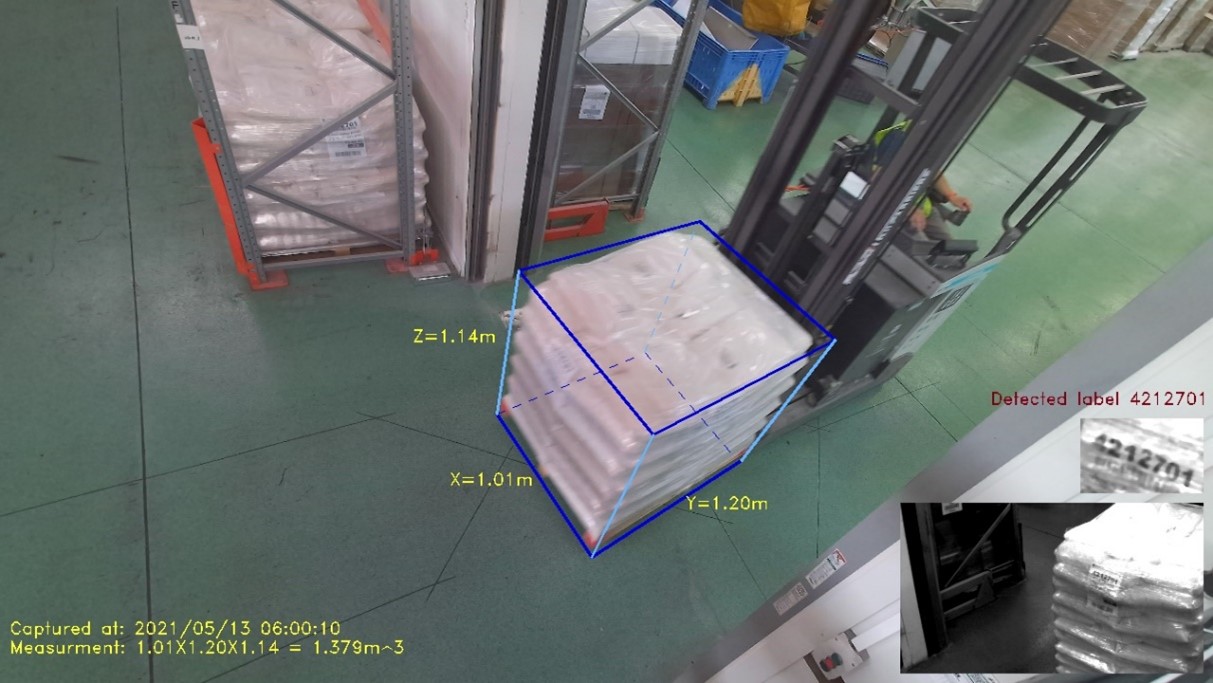

DS Smith, provider of sustainable packaging solutions, pilots digital 3D dimensioning to transform logistic operations

DS Smith is a leading provider of sustainable fiber-based packaging that improves transport and storage efficiency, boosts retail presentation and increases product sales for their customers worldwide. Headquartered in London, the company plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials and is constantly looking for ways to improve its production process. To optimize warehousing processes, the availability of real-time dimensional data of packaged product is essential. DS Smith creates packaging solutions that meet their customers‘ su...

Case Study: dnata digitally transforms air cargo ground operations with Microsoft 3D technology and Azure.

The aviation industry relies heavily on service providers to efficiently transport cargo between locations. Related processes which are part of what is known as ground operations, are poised to experience tremendous growth, according to Boeing’s World Air Cargo Forecast (2020-2039), “Overall, world air cargo traffic will more than double over the next 20 years, expanding from 264 billion revenue ton-kilometer (RTK) in 2019 to 578 billion RTKs in 2039.” dnata is one of the world’s largest air service providers that serves airlines and airports with everything from ground and cargo handling to inflight cater...

Case Study: Davidovich Group keeps its eyes on inventory with Azure 3D and AI in the cloud.

Davidovich chooses Microsoft’s 3D Time-of-Flight (ToF) technology to capture high-quality, precise 3D data of objects in motion in the company's warehouse to improve inventory management.

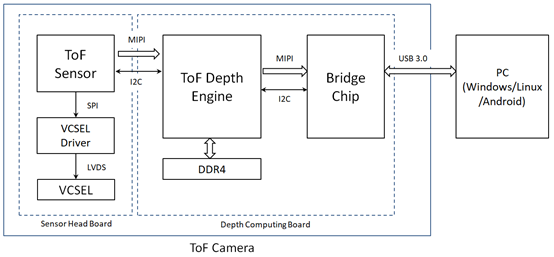

Time of Flight Camera – System Overview

The Azure Depth Platform program is delighted to have Paul O’Sullivan - System Engineer, and Nicolas Le Dortz - System Engineer Manager at Analog Devices as our guest blog authors for this edition of the Azure Depth Platform blog. Paul O'Sullivan Nicolas LeDortz Analog Devices (ADI) is building on the core Microsoft ToF pixel technology to deliver complete ToF solutions to a broad customer base in areas such as industrial factory automation, inventory management, automotive infotainment, augmented reality, computational photography and videography. This blog post will describe some of the advantages of c...

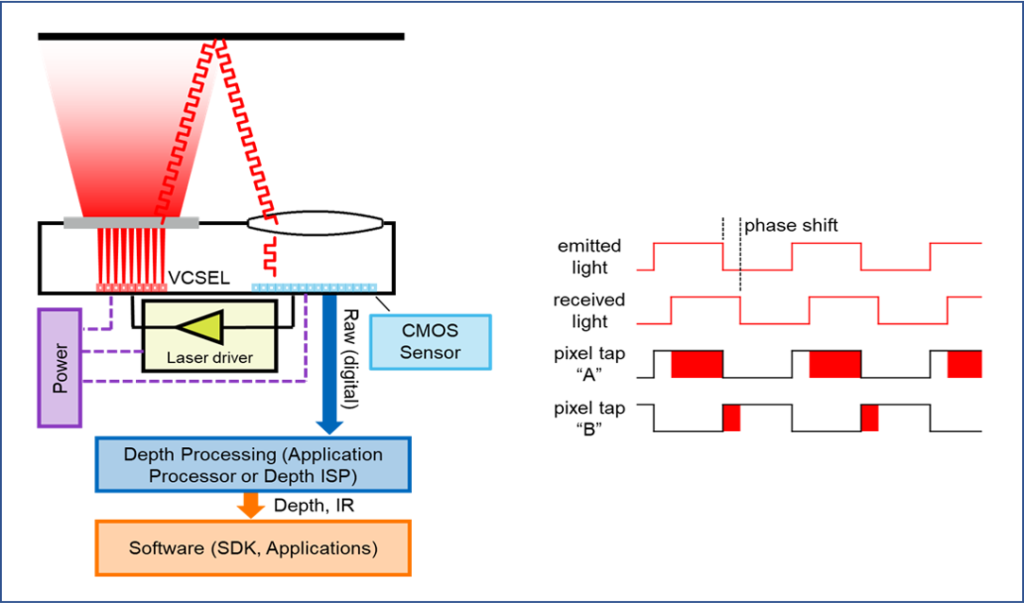

Understanding Indirect ToF Depth Sensing

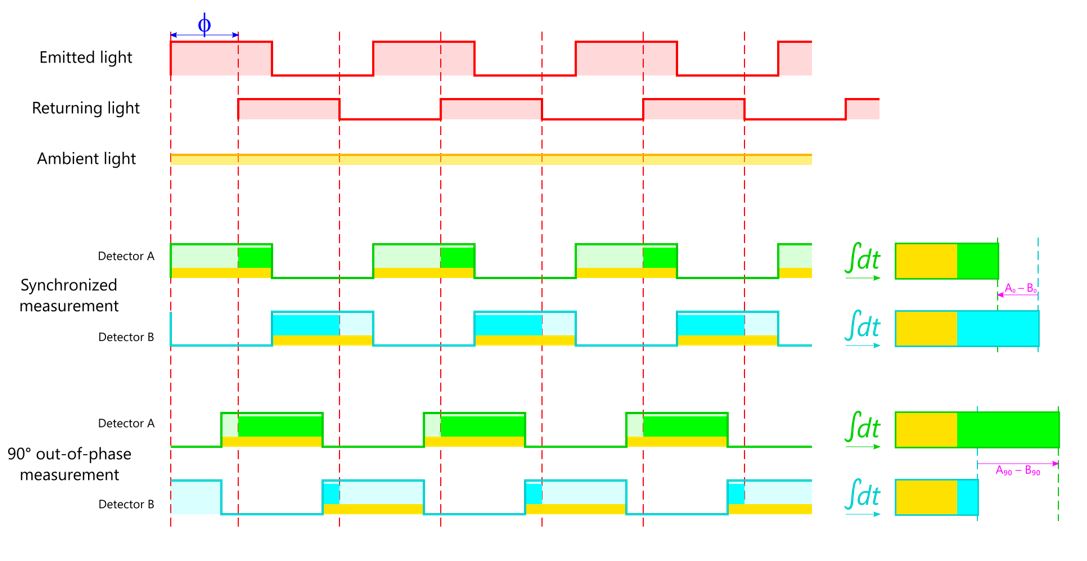

Now that you’ve had a chance to read the Intro to Indirect Time-of-Flight (ToF) post, let’s dig a little deeper into the mechanics behind the Microsoft implementation of time-of-flight depth sensing, as well as a couple functional advantages it presents. How does “Indirect” ToF work? To recap, “time-of-flight” refers to emitting light at an object and measuring how long it takes to bounce back and return, then converting the time measurement into distance using the speed of light, giving us the object’s shape and position in its surroundings. Figure 1. Generalized operation of time-of-flight sensing. In pra...

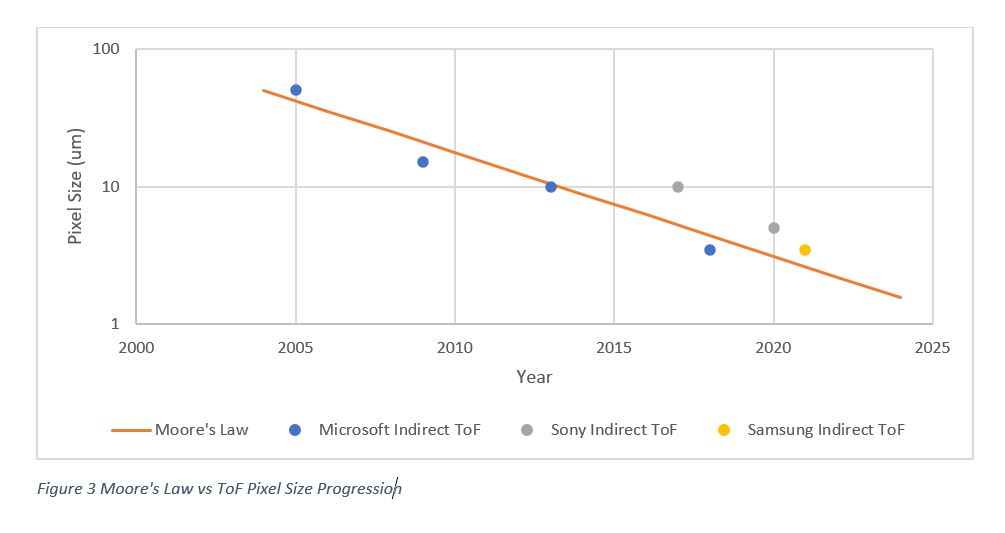

Moore’s Law for ToF Pixels

In 1975 Gordon Moore made a prediction which became famous as Moore’s law which states that the number of transistors in a microchip doubles every two years (or 18 months depending on who you talk to) (Figure 1). The simplified version of this law states that the processing power or processing speed doubles every two years. Translating to image sensors in general, does the number of pixels in a sensor double every two years or pixel size scale by √2 every two years. Not so fast, image sensors are more like analog chips than digital chips which do not scale proportionately with the technology node. RGB sensors hav...

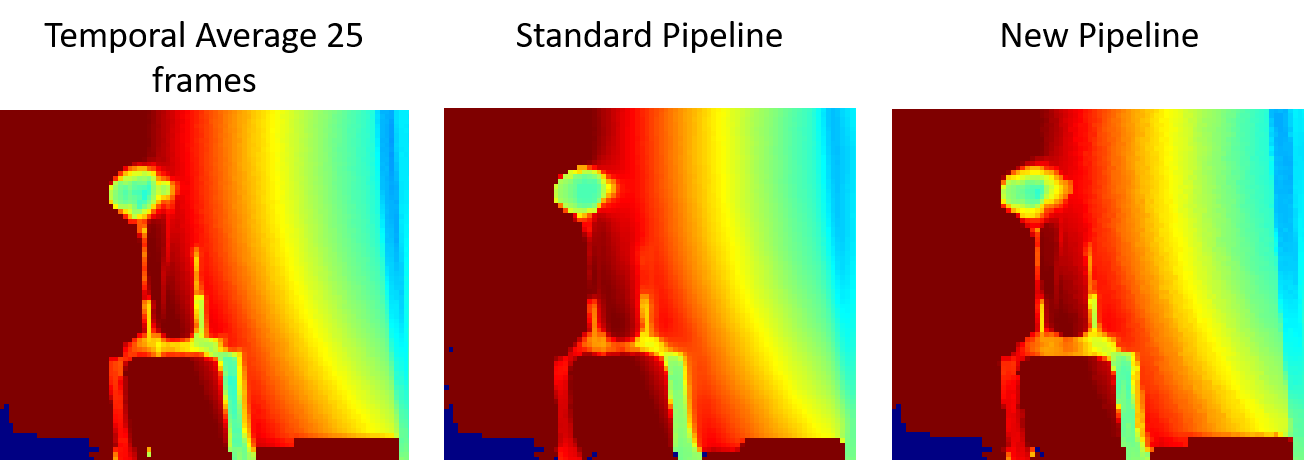

Raw-to-Depth: Advanced 3D Sensing

Brief: Microsoft ToF technology is now available to industry and Azure customers can access premium processing for enhanced 3D depth sensing that delivers improvements in spatial frequencies, ambience resilience, pixel resolution, processing time, and more. Microsoft has made a strategic decision to make its Time-of-Flight technology accessible outside of Microsoft, to enable camera makers, solution providers, and ISVs to drive innovative 3D sensing capabilities across multiple industries and scenarios, such as: Robotics, IoT, logistics, factory automation, retail, fitness, healthcare and more… Working across...