Overview

Davidovich Group is a producer and wholesaler of bread and pastry products that has been supplying Israelis with baked goods for over 50 years. A successful bakery strives to meet the fluctuating demand for their products. The bakery operations involve creative offerings, but also product and a repeatable process. It’s a regulated industry where core products’ price is controlled leaving low profit margins. The raw materials and the products have limited shelf life that needs to be monitored and managed. Profitability relies on an efficient, automated operation, run at scale. Any disruption to production or shrinkage has an out-sized effect on the bottom line. Davidovich adopts modern technology and methods to help them improve efficiency and reduce costs.

Situation

One of the perennial problems logistics operation faces is product shrinkage and addressing it head-on is a business priority. With good inventory management practices food providers can optimize stock and reduce unnecessary loss due to spoilage, theft, and operational errors. In Davidovich’s case, they have automated portions of their warehouse operations and practice best-in-class inventory management and still they recognize that staying on top of technology is the key to remaining competitive in a commodity market. As part of their digital transformation, the company is updating systems and operations to reduce loss, improve delivery times and increase order accuracy.

Davidovich researched solutions and reached out to potential providers that would help them update their systems to capture, identify and measure palleted products. The requirements were clear—any solution must integrate with the existing infrastructure and could not disrupt production.

Challenges

Davidovich explored existing market solutions, but they did not satisfy the requirements due to a large upfront investment and ongoing maintenance costs. The warehouses would also need to be retro-fitted that would require operations be halted for some time. That’s when Davidovich turned to Agent Factory, experts in applying custom AI solutions for 3D machine vision. What the bakery needed was a means to accurately determine what product they had on hand as the starting point to more robust inventory management—a solution that would literally identify product coming and going from their warehouses 24 hours a day, every day.

Solution

There were multiple technical challenges to keep the chosen solution simple to maintain and within budget. Traditional 2D cameras do not have the notion of depth and without it dimensioning cannot work. Laser-based systems or multiple camera arrays could potentially capture 3D depth images but require sophisticated equipment which the require cargo to be placed at a designated location to capture dimensions.

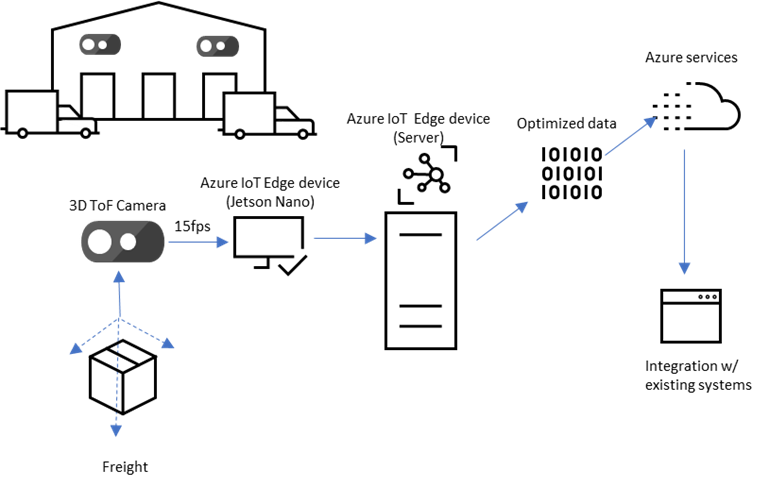

The solution Davidovich ultimately chose is based on Microsoft’s 3D Time-of-Flight (ToF) technology that can capture high-quality, precise 3D data of objects in motion. ToF-based cameras positioned at the entrances and exits of the company’s warehouses capture images of incoming and outgoing freight including and algorithmic processing determines the dimensionality. The solution aligned seamlessly with Davidovich’s existing processes, and camera installation only required simple rack mounts and subsequent calibration to ensure correct positioning.

“Leveraging Microsoft’s 3D Time of Flight technology and the Azure cloud platform we were able to develop a solution rapidly and cost-effectively with the accuracy, field of view and range required.”

Boaz Ein-Gil, CEO, Agent Factory

The solution also had to support high data rates from multiple capturing points at all the entrances of a storage area and track both incoming and outgoing freight. The amount of data captured is large and complex to process; a single depth camera produces ~2.5TB (at 15fps) of unfiltered data a day. With so much data to store and process the solution had to balance the costs of processing data on-prem with processing in the cloud. The data is processed on prem so only the most useful data is sent to the cloud for analysis to avoid unnecessary bandwidth costs.

“Integrating our cloud analysis with Azure Cognitive Services allowed us to bring world-class label detection into our solution in no time.”

Avihai Lifschitz, Chief Scientist, Agent Factory

Agent Factory chose Azure IoT Edge as the runtime platform to run process-intensive workloads on top of Jetson Nano compute with Microsoft-based 3D ToF cameras. Azure IoT Edge is also used as the gateway to Azure and offers a ready-made infrastructure to support remote deployment and management and monitoring of the on-prem software components which saved considerable development time.

In addition, Agent Factory designed a resilient, high-performance processing pipeline to drastically reduce data size down to ~0.01% of total captured data so that only the most useful frames from each activity are uploaded to the cloud. The pipeline includes a dedicated, proprietary trained DNN classifier that uses depth-based images as input.

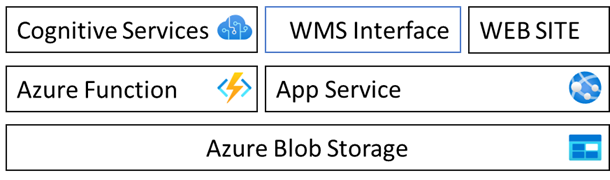

On Azure, combining Blob storage, Azure Functions and Microsoft Cognitive Services allows for cost efficient processing of uploaded frames to extract label data and dimensions of the freight. In addition, Azure App Service allowed Agent Factory to rapidly develop an online portal that makes the optimized data available to Davidovich through a secure web portal.

Benefits

Leveraging a selection of proven combination of Azure technologies and services dramatically saves development costs. The processing of 3D data and images requires complex algorithms with high computation demands that are more easily met in the cloud than with on-prem processing. With that, providing seamless experience requires constantly capturing 3D data that quickly becomes too large to be pushed to the cloud requiring a hybrid of on-prem and cloud components.

“With this solution, we are getting the desired extra level of assurance managing our inventory with a minimal investment.”

Benny Davidovich, Chief Technology Officer, Davidovich Group

The 3D cameras featuring Microsoft’s best-in-class breed, ToF depth sensing technology provide the wide fields of view and image quality necessary to capture freight moving in and out of the warehouse. Agent Factory designed the solution so that the on-prem hardware and software that captures activities 24/7 can distill the captured data to a reduced footprint that can be easily pushed to the cloud. Once data reaches the cloud, it is processed to extract the business value by executing a dimensioning algorithm and combines it with label data, to produce digital logs with visual evidence of all freight movement.

Developers considering 3D machine vision AI solutions have the advantage building solutions with Azure IoT Edge on-prem and Azure cloud services because they serve as the foundation to cost-efficient 3D solutions. Solutions based on the Azure Depth Platform readily scale based on customer need and can reach hundreds of deployed cameras working in parallel. Customers can make their logistic processes smarter which directly translates to cost savings. Davidovich saw a return on their investment within two quarters.

0 comments